Check labels for originality and compare them with order data.

Check the packaging for originality and damage.

Check whether the MSL and ESD protection measures are in place and intact.

Use a microscope with 40x magnification to examine product properties: dimensions, inscriptions, finishes.

Test range: Impedance: 25mΩ~40MΩ;

Frequency: 20Hz~3GHz;

Routine test parameters such as Q value, ESR, ESL, resonance frequency, etc.

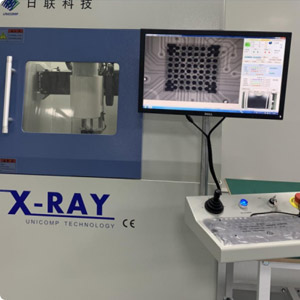

Analyze bond wires and chip placement in components.

Check connection contacts and solder joints (abnormalities, crack formation).

ESD and EOS damage analysis.

Storage of electronic components requires protection from electrostatic discharge. Therefore, our storage areas are ESD protected according to DIN EN 61340-5-1/-5-3.

Our warehouse structure is optimized to allow smooth inbound and outbound shipments to maintain on-time delivery and consistently high quality.

Click on the demand message, we will arrange the purchase for you as soon as possible.

WeChat

Scan the QR Code with WeChat